Aluminum alloy dust remover

This product is specifically designed for the removal of surface ash from various aluminum alloy workpieces after alkali and acid polishing. The operation is stable, and the ash removal effect is good, which can replace traditional nitric acid ash removal.

Product Introduction

This product is specifically designed for the removal of surface ash from various aluminum alloy workpieces after alkali and acid polishing. The operation is stable, and the ash removal effect is good, which can replace traditional nitric acid ash removal. The product meets the corrosion resistance standards of MIL-DTL-81706 and MIL-5541. Environmental protection and safety, easy operation, simple wastewater treatment, acidic product, fast speed, good effect, no damage to workpiece substrate, good durability, etc. During use, no toxic and harmful gases are generated, meeting R0HS requirements, and environmentally friendly.

Product Feature

| √ Fast oil and wax removal cleaning speed |

| √ No corrosion or damage to the workpiece |

| √ Long service life of tank liquid |

| √ Water-based safety, easy to rinse, no residue |

| √ Low odor, non flammable and non explosive |

| √ Meets EU RoHS indicator requirements |

Quick to clean, non corrosive, easy to rinse, environmentally friendly, odorless, and not harmful to hands

Physical and chemical indicators

| Appearance | Colorless to slightly yellow liquid | Density | 1.04~1.06g/L |

| PH | 3-5 or 6-9 or 11-13(working fluid) | Secure | Non combustible non corrosive |

| Environmental protection | Phosphorus free, halogen-free, compliant with EU RoHS requirements | ||

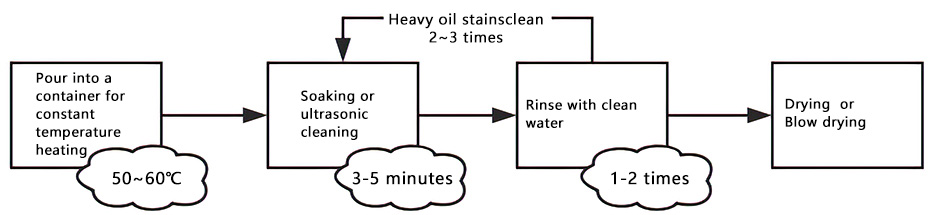

Process Flow

Precautions for use

USAGE

Constant temperature immersion cleaning or ultrasonic cleaning

USAGE METHOD

Dilute in proportion to the working solution, heat to 50-60 degrees, soak at a constant temperature for 5-10 minutes, or clean with ultrasound for 2-3 minutes.For heavy oil contaminated workpieces, extend the cleaning time or use multiple grooves to thoroughly clean them.

MAINTENANCE

1. Regularly check the temperature and liquid level of the tank liquid, replenish water in a timely manner, and add the corresponding proportion of the original liquid.

2. Regularly replace the tank liquid according to the specified time.